BRDECO Wall Panels on the BIG5 Dubai 2017

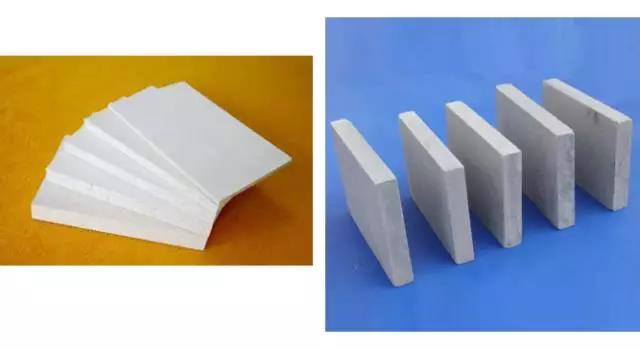

Since 1980, the BIG5 Dubai 2017 exhibition, as the largest construction exhibition in the Middle East with 30-years history and is the only place to meet thousands of international construction equipment and building materials suppliers from all of the world. It attracted more then 2500 exhibitors from all over 60 countries and areas. This exhibition bring a good business communication opportunities for BRDECO and other Chinese companies to explore the huge international market. The insulation building materials have attracted great attentions of the customers. A large number of capital construction projects in Middle East area bring large demands of the insulation building materials. In this world class exhibition, BRDECO had face to face communications with customers in Middle East area, showing and describing our energy-saving building materials. This exhibition sees the huge market prospect of the PU Sandwich Panel , wall cladding systems , and truss deck manufactured by BR